3 Roller Pipe Bending Machine For Sale

A multipurpose industrial instrument, the 3 Roller Pipe Bending Machine is made to effectively form pipes made of copper, stainless steel, and steel. It employs three rollers, positioned in a triangular configuration, to bend pipes smoothly and consistently. This machine is equipped with hydraulic or electric controls, allowing operators to adjust the bending radius and angle with ease, ensuring accuracy in every bend. Its robust construction and durable components makeroll cage pipe bender suitable for heavy-duty applications in industries like automotive, aerospace, construction, and pipe roller bender 4000 lbs 2 ton Steel Portable Gantry Crane manufacturing.

With its advanced capabilities, the 3 Roller Pipe Bending Machine offers flexibility in producing a wide range of bent pipe configurations, including U-bends, S-bends, and custom shapes, meeting the diverse needs of clients and projects. Whether for mass production or bespoke fabrication, pipe bender roll cage machine delivers efficient and reliable performance, enhancing productivity and quality in pipe bending roll bar pipe bender operations.

Key Features :

- Triple Roller Design: Incorporates three rollers to ensure precise bending of pipes, enhancing accuracy and consistency in the bending best pipe bender for roll cages process.

- Versatile Bending Capabilities: It can bend various types of pipes, including round, square, and rectangular profiles, providing versatility for a wide range of applications.

- Ease of Operation: Designed with user-friendly controls and intuitive interfaces, enabling operators to efficiently set parameters and execute bends with minimal training or expertise pipe bender for roll cage 48” Skid Steer Articulating Swing Arm Brush Cutter required.

- High Precision Bends: Utilizes advanced bending technology to achieve high precision bends with minimal deformation, ensuring superior quality and integrity of the bent pipes.

- Durable Construction: Constructed with robust materials and components, ensuring durability and longevity even under demanding industrial conditions.

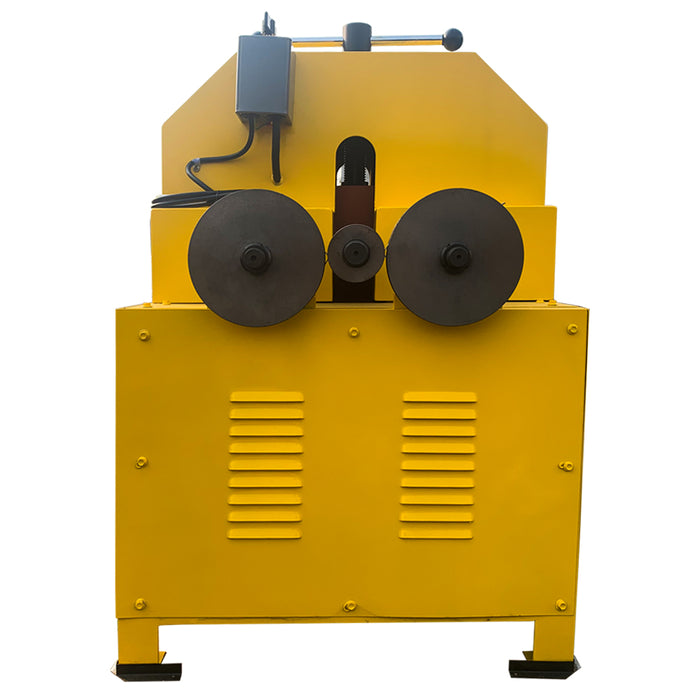

- Compact Design: Features a compact footprint, making it suitable for use in space-constrained environments without compromising on performance or functionality.

- Efficient Workflow: Streamlines the bending process, reducing production time and increasing overall productivity, making it an ideal solution for high-volume manufacturing pipe bender roller operations.

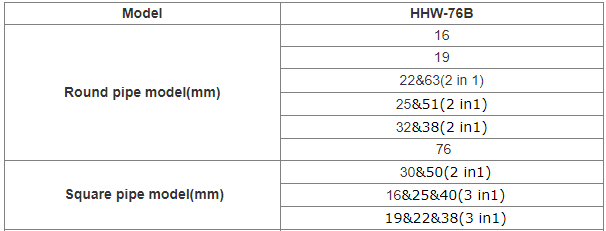

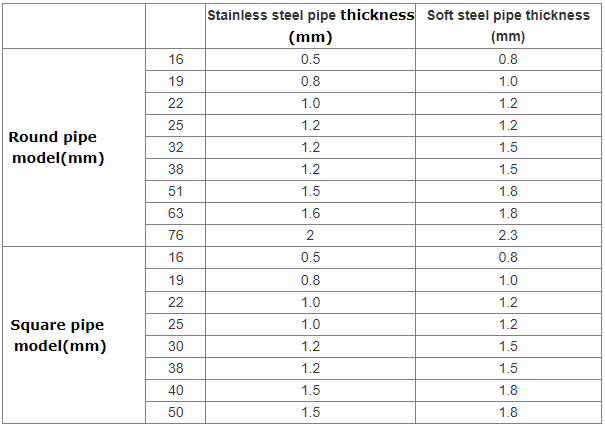

Technical Information:

Voltage: 110V

Packaging:

| Electric Motor: | 220V/380V,1.5KW, 1400RPM |

| Dimension: | 29″ × 21″ × 40″ |

| Shipping Weight: | 551.15 lbs |

Reviews

There are no reviews yet.